Say Goodbye to Traditional Top-Drawer Packaging, Embrace the New Era of Bottom-Drawer Packaging

Fully Automated Bottom-Drawer Tissue Production Line Solution: Increase Production Efficiency by 30% and Reduce Operating Costs by 25%

Does your production line face these challenges?

🔴Disadvantages of Traditional Top-Drawer Packaging

1

2

3

4

🔴 Changes in Market Demand

Innovation

Consumer preferences are shifting towards bottom-drawer packaging, reducing the competitiveness of traditional products.

Need

Retailers are demanding more compact packaging to save shelf space.

Adapting to Diversity

Environmental trends are driving reduced plastic packaging, which existing production lines cannot adapt to.

produce

Increased small-batch, multi-variety orders are causing insufficient production line flexibility.

These are not just your problems; we have provided systemic solutions for 500+ paper product companies.

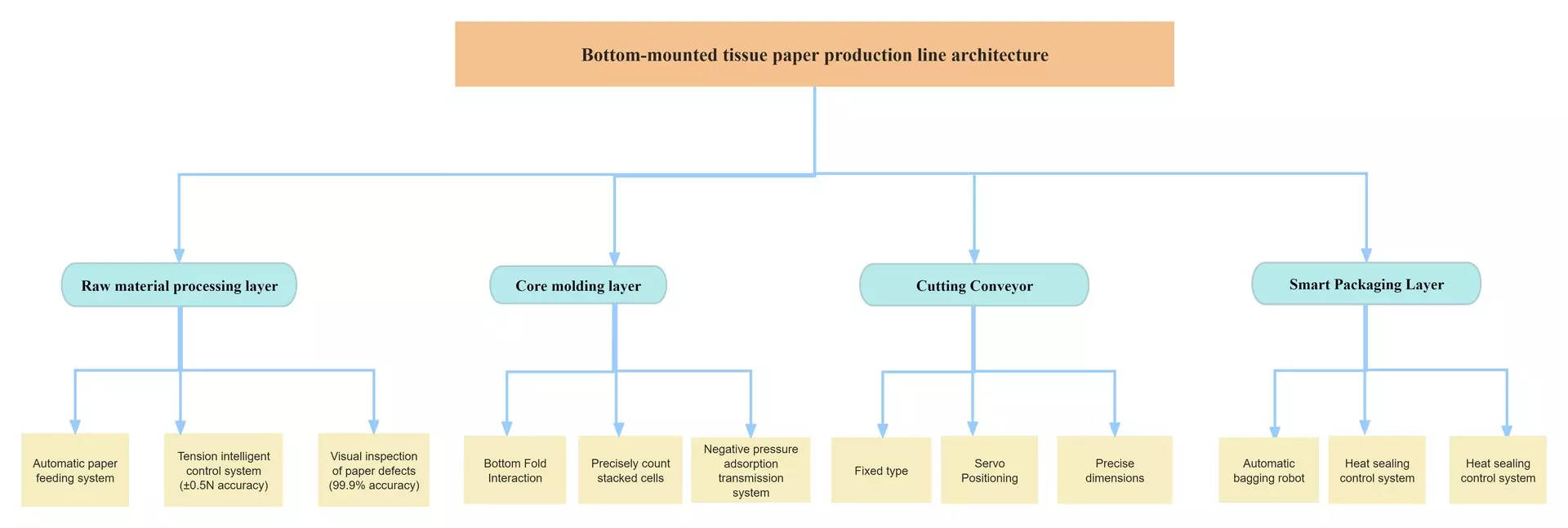

Production Line Process

Production line parameters

|

1 |

设计速度 |

130米/分钟 |

|

2 |

生产速度 production rate |

100-120 m/min |

|

3 |

常规辊面幅宽 width of conventional roll surface |

1550 mm,折叠宽度170、175、180、190、200可选。 1550 mm, with foldable widths available in 170,175,180,190, and 200 mm options |

|

4 |

适应原纸 adapted base paper |

草浆纸,木浆纸,甘蔗浆纸,竹浆纸等 Cellulose paper, wood pulp paper, sugarcane pulp paper, bamboo pulp paper, etc. |

|

5 |

原纸克重定量 weight of base paper |

三层,每层克重14-18g/㎡;四层,每层克重11.5-15g/㎡ Three-layer construction, each layer weighing 14-18 g/m²; four-layer construction, each layer weighing 11.5-15 g/m². |

|

6 |

成品高度 Finished product height |

最小20mm,最大400mm Minimum 20mm, maximum 400mm |

|

7 |

主机墙板结构 host wall panel structure |

墙板框架式,厚度40mm Wall panel frame, thickness 40mm |

|

Model型号

|

SL-220S

|

|

Paper cutting specifications

切纸规格 |

L:100-200mm;W:200-450mm;H:80-120mm

长:100-200mm;宽:200-450mm;高:80-120mm |

|

Stable production speed 稳定的生产速度

|

150-200cuts/min 150-200切/分钟

|

|

Machine power 机器功率

|

13KW

|

|

Weight 重量

|

2000KG

|

|

Dimension(main machine) 尺寸(主机)

|

L1910mm*W1850mm*H1950mm 长 1910mm*宽 1850mm*高 1950mm

|

|

Power supply type 电源类型

|

three-phase 380V/50HZ 三相 380V/50HZ

|

|

Air pressure 气压

|

0.5-0.8Mpa

|

|

Model型号

|

ALX-270S

|

|

Design Speed 设计速度

|

32 packets/min 32包/分钟

|

|

Stable Production Speed 稳定的生产速度

|

28-30 packets/min 28-30包/分钟

|

|

Machine Power 机器功率

|

10KW

|

|

Weight 重量

|

1500KG

|

|

Dimensions (Main Machine)

尺寸(主机) |

L3800mm X W1560mm X H1700mm

长 3800mm x 宽 1560mm x 高 1700mm |

|

Power Supply Type 电源类型

|

Three-phase 380V/50Hz 三相 380V/50Hz

|

|

Air Pressure 气压

|

0.5-0.8Mpa

|

|

Package Size 包装尺寸

|

W125-250mm-H85-130mm

|

|

Packing Material 包装材料

|

PE, AP and other double-sided hot-sealed prefabricated bags

PE、AP 等双面热封预制袋 |

Client Cases

Ailixing tissue paper machine manufacturer, meeting all kinds of personalized requirements.

Fully automatic bottom drawer production line

High-speed bottom-pull tissue production line