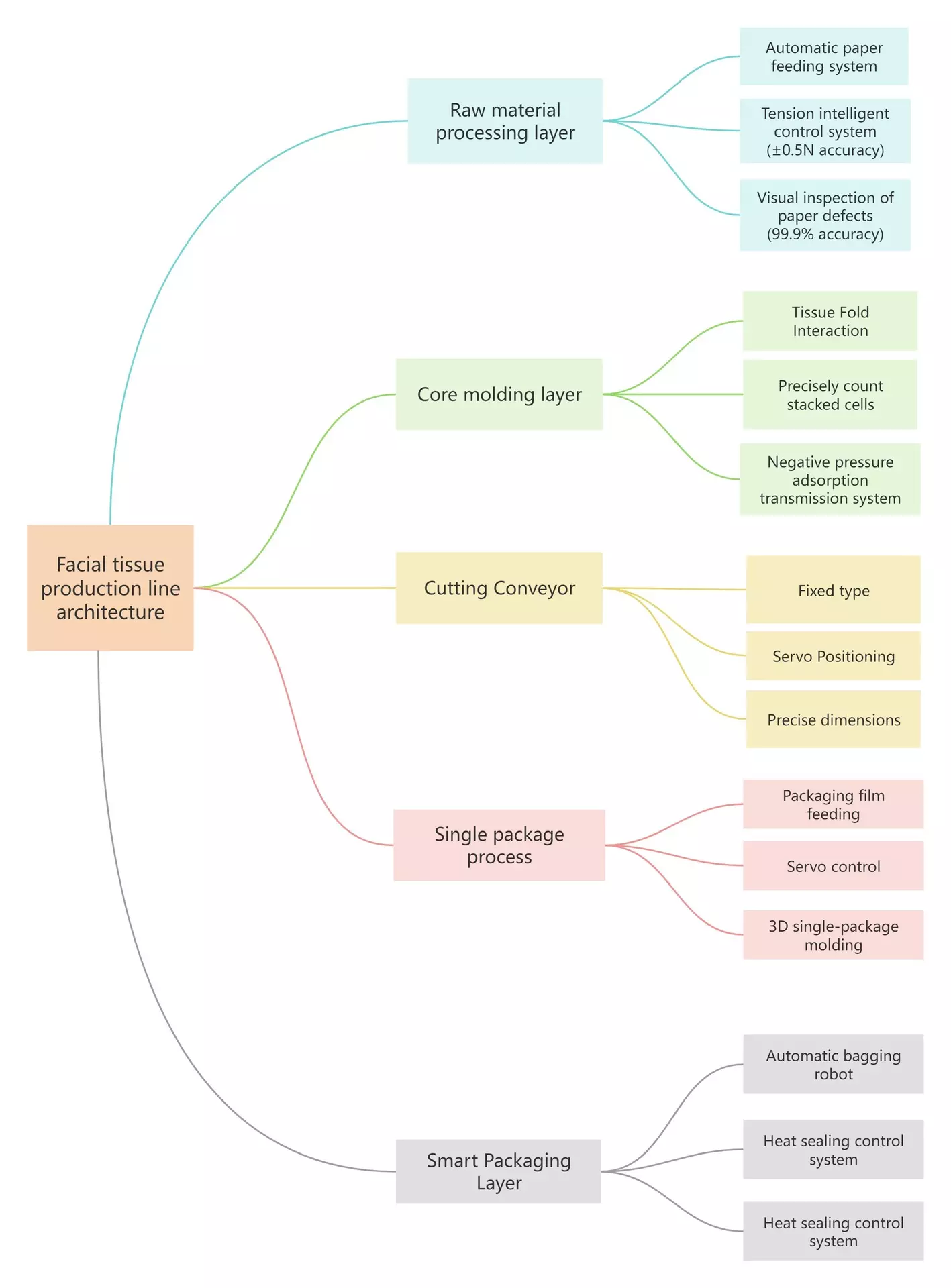

Intelligent Soft-Pack Facial Tissue Fully Automated Production Line Solution

Achieving high-speed production of 60,000 packs in eight hours, with a defect rate of less than 0.1% and a packaging perfection rate of 99.5%

Traditional production line vs smart production line

Breakthrough in Precision

Breakthrough in Precision: Folding accuracy improved from ±1.5mm to ±0.5mm

Technical Support: Nanoscale servo positioning + real-time visual compensation

Flexible Upgrade

Flexible Upgrade: Specification Switching Reduced from 3 Hours to 15 Minutes

Technical Support: Parameter Recipe Memory + Quick Mold Change System

Quality Leap Forward

Quality Leap Forward:Defect rate reduced from 2% to <0.1%

Technical Support: Machine vision full inspection + intelligent judgment

Production line video

Your tissue machine expert -- Ailixing

Facial tissue production line

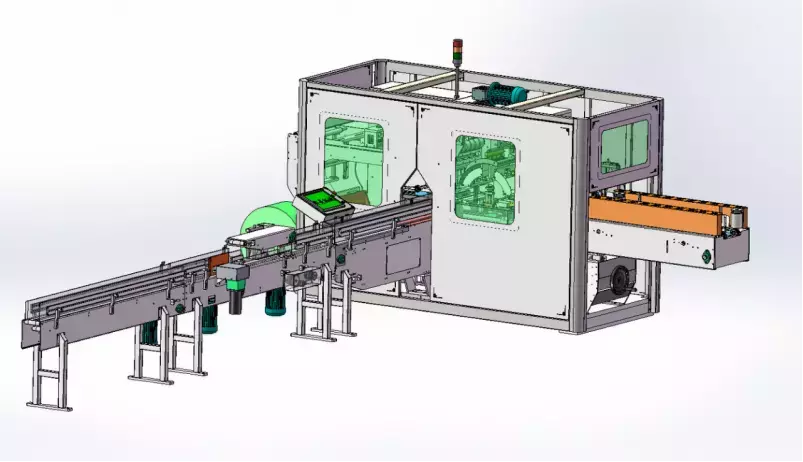

Tissue packaging machine

Tissue packaging machine

Facial tissue production line details

|

Design speed 设计速度

|

130 m/min 130 米/分钟

|

|

Production speed 生产速度

|

100-120 m/min 100-120 米/分钟

|

|

Conventional roll width 常规卷宽

|

1550 mm, folding widths available: 165, 170, 175, 180, 190, 200, and 210 mm.

1550 毫米,可用折叠宽度:165、170、175、180、190、200 和 210 毫米。 |

|

Suitable base paper 合适的原纸

|

Straw pulp, wood pulp, sugarcane pulp, bamboo pulp, etc.

秸秆浆、木浆、甘蔗浆、竹浆等。 |

|

Base paper weight 原纸重量

|

Three-ply, 14-18 g/m2 per layer; four-ply, 11.5-15 g/m2 per layer.

三层,每层 14-18 g/m2;四层,每层 11.5-15 g/m2。 |

|

Finished product height 成品高度

|

Minimum 20 mm, maximum 400 mm

最小 20 毫米,最大 400 毫米 |

|

Mainframe wall panel structure

主机墙板结构 |

Wall panel frame, 40 mm thickness

墙板框架,40 毫米厚 |

|

Model 型号

|

SL-320S

|

|

Paper cutting specifications

切纸规格 |

L:90-210mm;W:80-110mm;H:25-120mm

长:90-210mm;宽:80-110mm;高:25-120mm |

|

Stable production speed 稳定的生产速度

|

250-300cuts/min 250-300切/分钟

|

|

Machine power 机器功率

|

7KW

|

|

Weight 重量

|

1500KG

|

|

Dimension(main machine) 尺寸(主机)

|

L1537mm*W1568mm*H1520mm 长 1537mm*宽 1568mm*高 1520mm

|

|

Power supply type 电源类型

|

three-phase 380V/50HZ 三相 380V/50HZ

|

|

Air pressure 气压

|

0.5-0.8Mpa

|

|

Product delivery method 产品交付方式

|

Automatic material sorting

自动物料分拣 |

|

Design production speed 设计生产速度

|

15-180 bags/min 15-180袋/分钟

|

|

Maximum stable production speed

最大稳定的生产速度 |

160 bags/min 160袋/分钟

|

|

Product specification conversion completion time

产品规格转换完成时间 |

15 minute 15 分钟

|

|

Time to change packaging film

更换包装膜的时间 |

1 minute 1分钟

|

|

Packaging specifications 包装规格

|

Length 90-230mm, Height 30-90mm

长度 90-230mm,高度 30-90mm (Customizable) (可定制) |

|

Pattern position printing error adaptation range

图案位置印刷误差适应范围 |

+/-2mm vertically, +/-2mm horizontally

垂直 +/-2mm,水平 +/-2mm |

|

Overall size 整体尺寸

|

Feed conveyor length 4000mm

进料输送机长度 4000mm Main unit length 3812mm, width 968mm, height 1600mm 主机长 3812mm,宽 968mm,高 1600mm |

|

Machine weight 机器重量

|

2500KG

|

|

Packaging materials 包装材料

|

CPP double-sided heat sealing film

CPP 双面热封膜 |

|

Packaging film thickness 包装膜厚

|

0.03-0.05mm 0.03-0.05毫米

|

|

Maximum diameter of the capsule

胶囊的最大直径 |

480mm 480毫米

|

|

Diameter of wrapping paper core

包装纸芯直径 |

76mm 76毫米

|

|

Maximum width of the envelope

信封的最大宽度 |

330mm 330毫米

|

|

Gas source pressure 气源压力

|

6-8kg/cm2 6-8公斤/厘米2

|

|

Cabinet power supply 机柜电源

|

380 V 50HZ 380伏50赫兹

|

|

Total driving power 总驱动功率

|

6.5KW

|

|

Total heating power 总加热功率

|

2KW

|

|

Model 型号

|

ALX-260S

|

|

Design 设计

|

20-25 t/min 20-25吨/分钟

|

|

Stable production speed 稳定的生产速度

|

20-25 t/min(depending on product specifications)

20-25 吨/分钟(取决于产品规格) |

|

Machine power 机器功率

|

15KW

|

|

Weight 重量

|

1500KG

|

|

Dimensions (main machine)

尺寸(主机) |

L4105mmW1874mmH1765mm 长4105毫米宽1874毫米高1765毫米

|

|

Power supply type 电源类型

|

380V/50HZ 380伏/50赫兹

|

|

Air pressure 气压

|

0.5-0.8Mpa

|

|

Package size 包装尺寸

|

L200-400mmW120-400mmH90-180mm

长 200-400mm 宽 120-400mm 高 90-180mm |

|

Packing material 包装材料

|

PE, AP and other double-sided hot-sealed prefabricated bag

PE、AP 等双面热封预制袋 |