Tissue packaging machine: an intelligent solution to improve efficiency and quality

In the fast-paced modern production, tissue packaging machine has become one of the core equipment in the paper processing industry. Whether it is tissue paper, roll paper, wet wipes or napkins, efficient packaging can not only improve the appearance of the product, but also significantly reduce labor costs. This article will deeply explore **the types, working principles, key points for purchase and market trends of tissue packaging machines** to help you find the most suitable packaging solution.

1. Types and applications of tissue packaging machines

According to the packaging form and product requirements, tissue packaging machines are mainly divided into the following categories:

(1) Fully automatic tissue packaging machine

- Applicable products: soft tissue paper, boxed tissue paper

- Features: Automatically stack, bag and seal tissue paper, with a speed of **80-120 packs/minute**.

- Application scenarios: household tissue paper, hotel room supplies, and catering tissue paper packaging.

(2) Paper roll bag packaging machine

-Applicable products: toilet paper roll, kitchen paper roll

-Features: Automatically load single or multiple paper rolls into bags, supports **5-10 rolls/bag**, and has a production capacity of up to **100 bags/hour**.

-Application scenarios: supermarket retail packaging, wholesaler large packaging needs.

(3) Wet wipes packaging machine

- Applicable products: single wet wipes, multiple wet wipes packages

- Features: Leak-proof sealing design, compatible with aluminum foil bags, plastic films and other materials.

- Application scenarios: production of medical wet wipes, baby wet wipes, and disinfectant wet wipes.

(4) Fully automatic square tissue packaging machine

- Applicable products: folded square tissues, napkins

- Features: high-speed folding + counting packaging, suitable for B-end customers such as restaurants and cafes.

2. Working principle of tissue packaging machine

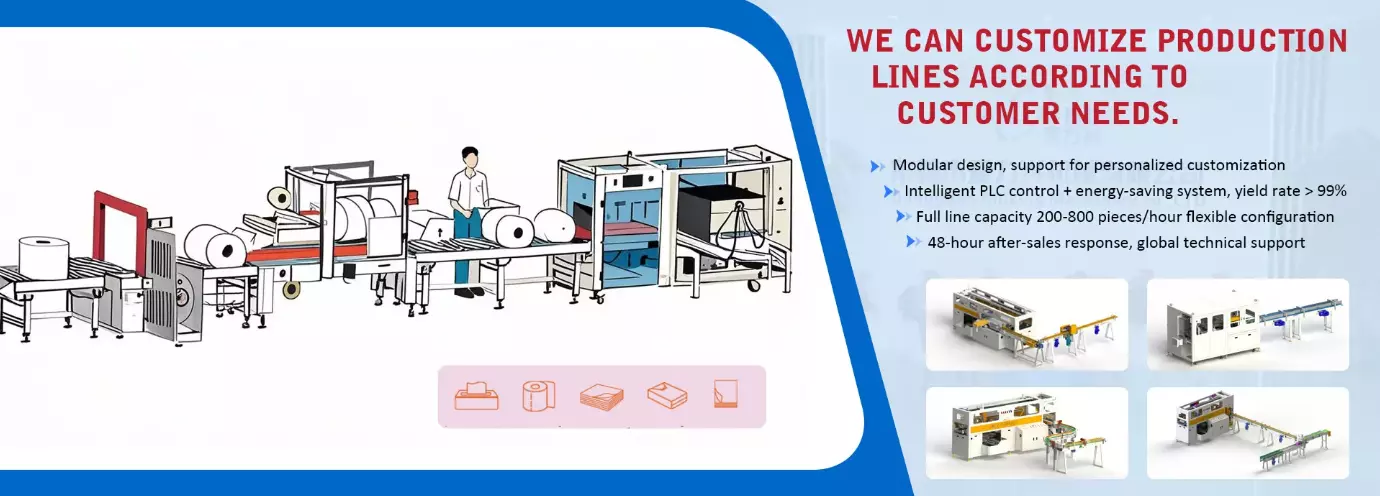

Modern fully automatic tissue packaging machines usually adopt PLC control system + servo drive, and the main processes include:

1. Automatic feeding → 2. Precise counting/paper stacking → 3. Bagging/film wrapping → 4. Hot pressing and sealing → 5. Coding/labeling (optional) → 6. Finished product output

Key technological innovation:

- Photoelectric sensor: Ensure the accurate number of tissues per pack, with an error of ≤0.1%.

- Modular design: Quickly change molds to meet the packaging needs of different specifications.

- Energy saving mode: Some models can reduce energy consumption by 30%, meeting environmental protection requirements.

3. How to choose a suitable tissue packaging machine?

(1)Clear requirements

- Product type (tissue paper/roll paper/wet wipes)

- Packaging speed (e.g. 80 packs/minute or 200 packs/minute)

- Packaging form (medium bag, single pack, gift box)

(2)Core parameter comparison

| Parameters | Economic type | Standard type | High-end type |

| Speed | 40-60 packs/minute | 80-120 packs/minute | 150-200 packs/minute |

| Accuracy | ±1mm | ±0.5mm | ±0.2mm |

| Automation | Semi-automatic | Fully automatic | Fully automatic + intelligent online |

(3)Key points for supplier evaluation

✅ Technology maturity (Are there any industry cases?)

✅ After-sales service (Does it provide installation, training, spare parts support?)

✅ Customization capability (Can it adapt to special packaging needs?)

4. Market trend: intelligence and sustainable development

- Intelligent online production: The packaging machine is linked with slitting machine and cartoning machine to realize unmanned workshop.

- Environmentally friendly packaging: The adaptation technology of degradable materials (PLA film, paper bag) is emerging.

- Internet of Things (IoT): Remote monitoring of equipment status, predictive maintenance to reduce downtime.

5. Conclusion

Choosing an efficient tissue packaging machine can not only improve product competitiveness, but also optimize production costs.

📞 Need free solution consultation? Please contact us for 1-on-1 equipment selection suggestions!

E-mail:

-

ailixingmachinery2018@gmail.com

-

WhatsApp/WeChat:+86 159 9985 2935